Ion Drive Propulsion: Types, Development, and Future Prospects

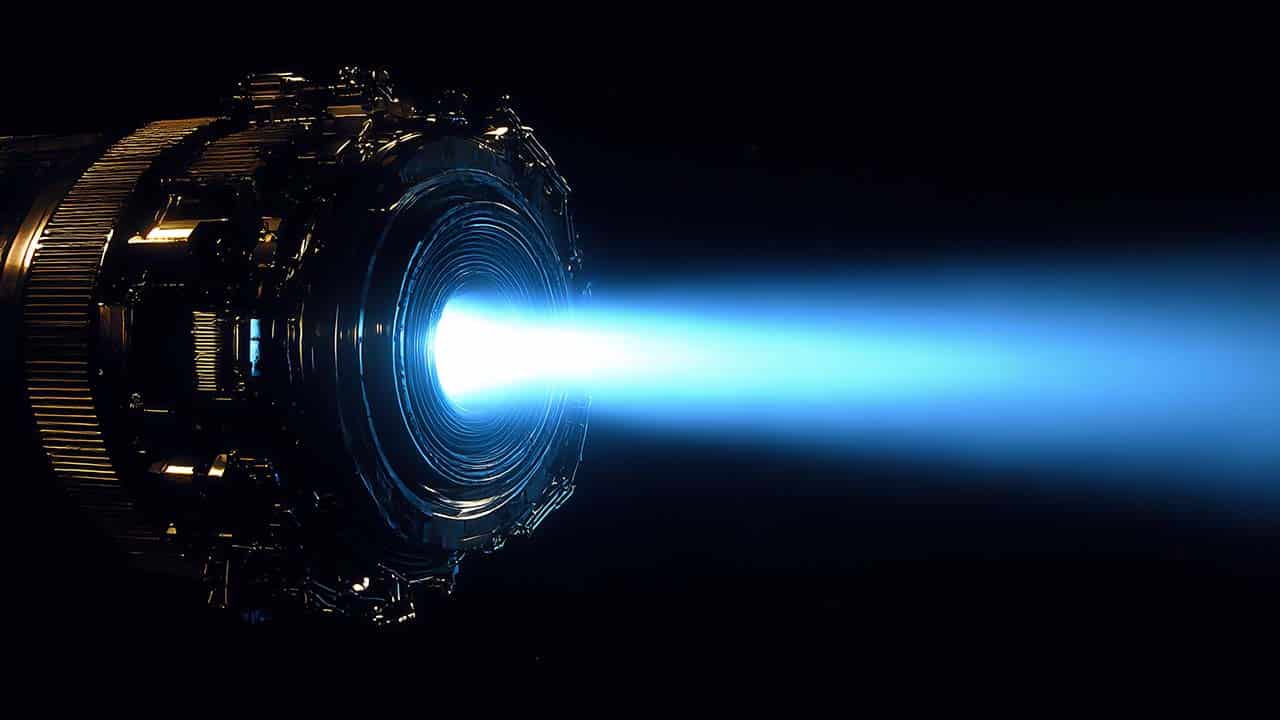

Ion drives – more broadly, electric propulsion systems – mark a sharp break from the explosive, high-thrust chemical rockets that opened the Space Age. Instead of brief bursts of force, ion drives accelerate charged particles to extreme velocities with electromagnetic fields, applying a gentle push that can last months or years. That quiet blue glow is quietly transforming spaceflight, from dense broadband constellations in low Earth orbit to deep-space probes tracing trajectories that chemical propulsion could never realistically afford.

What Ion-Drives Are and How They Are Used in Space

Ion drives operate by removing electrons from neutral atoms—typically xenon or krypton—to produce positively charged ions, which are then accelerated by electric or magnetic fields to extremely high exhaust velocities. This process yields propulsion efficiencies far beyond chemical rockets, because the energy input goes almost entirely into accelerating propellant mass rather than heating it. The resulting exhaust can reach tens of kilometers per second, which means that even tiny amounts of propellant can produce large cumulative changes in spacecraft velocity over time. The trade-off, however, is very low instantaneous thrust, making ion drives ideal for long-duration missions rather than rapid maneuvers.

In practical terms, this means ion engines excel in the vacuum of space, where resistance is nonexistent and spacecraft can afford to accelerate gradually for weeks or months. Satellites use them for orbit maintenance, station-keeping, collision avoidance, and end-of-life deorbiting. For example, geostationary satellites rely on electric propulsion to counter gravitational perturbations and solar radiation pressure, extending mission life while significantly reducing propellant mass. In low Earth orbit, commercial constellations use Hall-effect thrusters to correct drift, manage formation geometry, and ensure responsible deorbit procedures.

Deep-space missions particularly benefit from ion propulsion, as demonstrated by NASA’s Deep Space 1, Dawn, and ESA’s BepiColombo. These spacecraft accumulated extraordinary amounts of total Δv—far more than would be feasible with chemical propulsion alone—allowing them to visit multiple celestial bodies and execute precise orbital insertions. Ion drives have also enabled highly efficient spiral trajectories, gravity-assist sequences, and mission profiles that evolve dynamically in response to scientific or navigational needs.

As electric propulsion matures, its role continues to expand. NASA’s upcoming Lunar Gateway will rely on high-power Hall thrusters for orbital operations, embodying the next step in placing ion engines at the heart of critical exploration infrastructure. Over the next decade, electric propulsion is expected to underpin everything from space tugs and orbital logistics to Mars cargo delivery systems, signaling a shift from niche use to core mission architecture.

Types of Ion-Drive Designs & Related Propulsion Devices

“Ion drive” is really shorthand for a whole family of electric propulsion technologies that all accelerate charged particles, but do it in different ways and at different scales. Some are optimized for ultra-high efficiency and deep-space Δv, some for higher thrust at moderate efficiency, and others for tiny satellites or experimental high-power architectures. What ties them together is that they trade propellant mass for electrical power, using fields and plasmas instead of combustion to generate thrust.

Gridded Ion Thrusters (Electrostatic)

Gridded ion thrusters are the classic ion engines: a discharge chamber produces a dense cloud of ions from a neutral gas such as xenon, and a stack of electrostatic grids at high voltage pulls those ions out through microscopic apertures. The ions are accelerated to exhaust velocities of tens of kilometers per second, yielding specific impulses often above 3,000 seconds and extremely efficient use of propellant. Thrust levels, however, are tiny—typically tens to a few hundred millinewtons—even when the engine consumes several kilowatts of power. These thrusters are ideal for deep-space missions where long burn times are acceptable, and they have flown on missions like NASA’s Deep Space 1 and Dawn, as well as on commercial satellites for fine orbit control.

Hall-Effect Thrusters (Hall Plasma Thrusters)

Hall-effect thrusters are currently the workhorses of commercial electric propulsion. They employ an annular discharge channel with a radial magnetic field that traps electrons, which then ionize the propellant and create a quasi-neutral plasma. An electric field accelerates this plasma axially out of the channel, creating a characteristic blue exhaust plume. Hall thrusters typically offer specific impulses in the 1,200–2,000 second range and produce more thrust per kilowatt than gridded ion engines, making them attractive for orbit raising and station-keeping on both GEO satellites and large LEO constellations. Their relatively simple geometry, robust operation, and ability to be scaled from a few hundred watts to tens of kilowatts have made them a favored choice for many satellite platforms.

Colloid and Electrospray Thrusters

Colloid and electrospray thrusters operate at the opposite end of the power and thrust spectrum, targeting very small spacecraft that require precise, low-level control. Instead of ionizing a gas, they use intense electric fields to extract charged droplets or bare ions from a conductive liquid such as an ionic liquid or a liquid metal. The emitted particles are accelerated electrostatically, generating micronewton to millinewton levels of thrust with specific impulses often in the thousands of seconds. These devices are particularly well suited to CubeSats and nanosats, where propellant mass is extremely limited and fine attitude or formation control is critical, and they have been flown on multiple demonstration and operational missions in Earth orbit and beyond.

Pulsed Plasma Thrusters (PPTs)

Pulsed plasma thrusters are among the earliest electric propulsion systems to have flown in space, and they remain attractive for small spacecraft because of their simplicity and robustness. A typical PPT uses a solid dielectric propellant, such as Teflon, placed between electrodes; a high-voltage pulse vaporizes and ionizes a tiny layer of this material, and the resulting plasma is accelerated by the Lorentz force from the current and magnetic field. Each pulse produces a small “impulse bit,” and by firing at a controlled repetition rate, the thruster can deliver average thrust in the micro- to millinewton range. While their efficiency is modest compared to Hall or gridded ion engines, their lack of moving parts and straightforward design make them valuable for low-cost cubesat propulsion and attitude control.

Magnetoplasmadynamic (MPD) Thrusters

Magnetoplasmadynamic thrusters are high-power electromagnetic engines that promise significantly higher thrust than most other electric propulsion devices. They drive a large electric current through a plasma, and the interaction of this current with magnetic fields—either self-generated or externally applied—produces a strong J×B force that accelerates the plasma out of the nozzle. MPD thrusters can, in principle, operate at powers from tens of kilowatts to megawatts, producing Newton-level thrust with specific impulses ranging from roughly 1,500 to 5,000 seconds. However, they face challenges such as electrode erosion, thermal management, and the need for very large power systems, so they remain mostly in the experimental and conceptual stage rather than in routine operational use.

Electrothermal Thrusters (Arcjets and Resistojets)

Electrothermal thrusters like arcjets and resistojets occupy a middle ground between chemical and plasma propulsion. Instead of directly accelerating ions, they use electrical energy to heat a propellant—often the same hydrazine or nitrogen used in chemical systems—and then expand the hot gas through a nozzle to generate thrust. Resistojets use a resistive heater element, while arcjets create an electric arc to superheat the flow. These devices typically offer specific impulses in the 500–1,000 second range, better than monopropellant systems, with thrust levels suitable for station-keeping and modest orbit changes. They are comparatively simple and robust, making them attractive for missions that want some of the efficiency benefits of electric propulsion without the complexity of fully ionized plasma engines.

Advanced Plasma Concepts (VASIMR, HEMPT, and Others)

Beyond the established families, a range of advanced plasma thrusters are under active development, including VASIMR (Variable Specific Impulse Magnetoplasma Rocket), High Efficiency Multistage Plasma Thrusters, and other electrodeless or hybrid concepts. VASIMR, for instance, uses radiofrequency power to ionize and heat a plasma, with magnetic fields both confining the plasma and shaping it into a directed exhaust, allowing operators to trade thrust for specific impulse on the fly. Permanent-magnet Hall variants and multi-mode thrusters attempt to offer flexible performance regimes for different mission phases, from high-thrust orbit raising to high-efficiency cruising. While many of these designs have only flown in limited tests or remain in ground-based development, they point toward a future where electric propulsion can be tuned dynamically to mission needs rather than locked into a single operating point.

The RMF Plasma Thruster Using Inductively Pulsed Plasma Discharges

The Rotating Magnetic Field (RMF) plasma thruster represents one of the most intriguing “electrodeless” propulsion concepts under development, promising a fundamentally different approach to ion acceleration. Instead of using grids, cathodes, or magnetic channels like traditional thrusters, it relies on rapidly rotating electromagnetic fields to induce currents within a neutral gas. These currents generate a self-contained Field-Reversed Configuration (FRC) plasmoid—a compact, magnetically confined structure that behaves like a miniature, detached fusion plasma. Such a plasmoid can carry immense internal current, greatly amplifying the energy injected by the driving coils.

Once formed, the FRC is expelled out of the thruster by magnetic gradients and pulsed Lorentz forces, effectively ejecting discrete “plasma bullets” at extremely high speed. Because the process is entirely inductive, no physical electrodes contact the plasma, eliminating erosion—a major limiter of traditional electric thrusters. The exhaust is also quasi-neutral, so the system requires no electron-neutralizer cathode, simplifying overall hardware compared to gridded ion engines. These features could enable exceptionally high-power operation, with pulsed systems handling hundreds of kilowatts momentarily while maintaining long lifetimes.

Laboratory tests conducted at institutions like the University of Washington and University of Michigan show that RMF thrusters can reliably form and eject FRC plasmoids at kilohertz repetition rates. Researchers have demonstrated proof of principle in vacuum chambers, validating the underlying physics and exploring thrust generation, plasmoid stability, and efficiency. However, translating these early experiments into operational systems poses challenges: maintaining plasmoid uniformity, controlling high-voltage pulsed power electronics, and achieving stable long-duration operation are nontrivial engineering hurdles.

Even so, the RMF concept remains highly promising because it scales naturally with power—an essential quality for future high-thrust electric spacecraft. If engineers can refine power coupling, enhance efficiency, and ensure stable plasmoid production, RMF-FRC thrusters could become a leading candidate for megawatt-class propulsion. In a future where nuclear-electric spacecraft require electrodeless, high-power engines capable of sustained operation, RMF-FRC thrusters may offer one of the most compelling solutions.

Academic Programs and Universities Doing Research and Development

Universities form the backbone of electric propulsion research, driving innovation while training the engineers who shape the industry. In the United States, the University of Michigan’s Plasmadynamics and Electric Propulsion Laboratory (PEPL) stands as one of the premier institutions in the world. With enormous vacuum chambers and decades of expertise in Hall thrusters, nested-channel designs, and plasma diagnostics, PEPL has influenced nearly every major EP program. Similarly, Princeton’s Electric Propulsion and Plasma Dynamics Lab (EPPDyL) has contributed foundational research in plasma instabilities, plume behavior, pulsed inductive propulsion, and fundamental EP physics.

MIT’s Space Propulsion Lab has specialized in micro-propulsion, pioneering electrospray and colloid thrusters for CubeSats and other miniature spacecraft. These efforts have enabled precision formation flying, drag-compensation, and smallsat deep-space missions previously out of reach. Georgia Tech’s High-Power Electric Propulsion Lab (HPEPL) leads investigations into >100 kW thrusters, extreme-lifetime models, and air-breathing EP for ultra-low Earth orbit. Each of these labs contributes complementary expertise that collectively advances the performance, reliability, and scalability of ion drives.

Internationally, European universities under ESA’s EPIC and Horizon 2020 programs have made major strides in permanent-magnet Hall thrusters, high-efficiency gridded engines, and air-breathing ionization systems. Institutions such as Politecnico di Milano, the University of Stuttgart, and the University of York conduct extensive research into advanced materials, plasma modeling, and propulsion architectures tailored to European mission needs. Russian institutions like OKB Fakel’s partner universities continue to refine Hall-effect technologies with decades of operational heritage.

Across Asia, China’s universities—including Northwestern Polytechnical University and Beihang University—collaborate with state aerospace institutes to develop indigenous Hall thrusters and electrothermal propulsion systems. India’s emerging private space sector, supported by ISRO and institutions like the Indian Institute of Science, has also begun producing high-performance Hall thrusters for near-term commercial missions. Together, these global research centers form a robust ecosystem that pushes electric propulsion toward higher power, greater reliability, and broader mission applicability.

Companies That Manufacture Ion-Drives

Commercial development of electric propulsion has accelerated dramatically over the past decade as satellites have shifted toward mass efficiency, flexible mission profiles, and long operational lifetimes. In the United States, Aerojet Rocketdyne (now part of L3Harris) remains a dominant supplier, producing both Hall-effect thrusters and gridded ion engines for GEO comsats and deep-space probes. Its XR-series Hall thrusters and XIPS ion engines have flown on dozens of spacecraft. Busek Co. is another major U.S. player, offering a complete range—from electrospray thrusters for CubeSats to multi-kilowatt Hall engines supporting NASA’s Lunar Gateway.

Startups have also reshaped the market. Accion Systems’ TILE microthrusters are now standard on many CubeSat buses, providing reliable and low-cost propulsion. Apollo Fusion (acquired by Astra) offers compact Hall thrusters ideal for small constellations. RF plasma thruster companies like Phase Four are pushing alternative architectures, aiming to further reduce complexity and manufacturing cost. As commercial constellations scale into the thousands of satellites, these new entrants are crucial to meeting volume and cost demands.

In Europe, Airbus, Thales Alenia Space, ArianeGroup, and SITAEL maintain a robust and mature electric propulsion ecosystem. Safran’s PPS-series Hall thrusters, along with Thales’ ion engines, power many ESA missions and commercial GEO platforms. ENPULSION and Exotrail serve the smallsat market with mass-produced FEEP and Hall thrusters. Russia’s OKB Fakel remains historically important, having developed the widely used SPT-100 and its derivatives, which fly on satellites around the world.

China and India have rapidly expanded their domestic capabilities. China’s CASC and CAST produce Hall thrusters for national GEO and LEO satellites, including operational all-electric platforms. Bellatrix Aerospace in India has developed Hall thrusters and microwave electrothermal engines for regional and commercial customers. With electric propulsion now crucial to satellite competitiveness, the global supply chain continues to diversify, accelerate, and innovate.

How Many Satellites Currently Use Them and Projected Market Growth

The number of satellites using electric propulsion has grown rapidly as costs have fallen and mission requirements have become more demanding. Early in the 2000s, only a handful of satellites—mostly GEO comsats and specialized deep-space probes—used ion drives. By the late 2010s, the figure had risen into the hundreds. Today, the proliferation of LEO constellations has pushed adoption into the thousands, with Starlink alone deploying over 7,000 satellites equipped with krypton-fueled Hall thrusters. Virtually every major GEO satellite ordered today includes electric propulsion, whether for station-keeping or full electric orbit raising.

Market forecasts reflect this dramatic shift. The global electric propulsion satellite market is projected to grow from around $17 billion in 2025 to more than $30 billion by the early 2030s. This expansion is driven not only by the sheer number of satellites being launched, but also by the increasing reliance on EP for orbital sustainability, precise maneuvering, and mission longevity. As constellations multiply, the need for efficient drag compensation, safe disposal, and collision avoidance will drive even wider adoption of EP systems.

In GEO, electric propulsion’s dominance is now well established. Fully electric orbit-raising missions are routine, saving hundreds of kilograms of propellant and significantly reducing launch mass. This allows operators to use smaller rockets or pack more payload into each mission, directly improving profitability. In LEO, electric propulsion is becoming essential for constellation management, enabling dynamic reconfiguration, inclination adjustments, and atmospheric drag counteraction, especially for satellites operating below 600 km.

Looking forward, demand for in-space services—such as orbital transfer vehicles, debris removal systems, and inspection spacecraft—will further accelerate EP growth. These vehicles require large Δv budgets and must perform numerous maneuvers efficiently, making electric propulsion the natural choice. The combination of mass savings, operational flexibility, and environmental responsibility positions ion drives as one of the fastest-growing technologies in orbital infrastructure.

How Ion-Drives Will Evolve from Doing Orbital Adjustments to Providing Longer-Range Propulsion

Ion drives have already transitioned from performing minor station-keeping tasks to enabling full orbit raising, and they are now poised to dominate propulsion for deep-space logistics and cislunar infrastructure. The next decade will see electric propulsion integrated into large-scale spacecraft architectures where it serves as the primary engine for long-duration transfer missions. NASA’s Lunar Gateway Power and Propulsion Element exemplifies this trend, with 12 kW-class Hall thrusters providing all major orbital maneuvers in cislunar space.

As solar arrays become lighter and more efficient, high-power solar-electric spacecraft will be capable of transporting cargo to Mars, orchestrating multi-spacecraft deep-space missions, and supporting distributed exploration architectures. These electric “space tugs” can deliver habitats, fuel depots, and scientific payloads across vast distances at a fraction of the cost and propellant mass required by chemical propulsion. Their ability to operate continuously—accumulating huge amounts of total Δv over months—makes them ideal for interplanetary logistics.

Small spacecraft, too, will benefit from this evolution. Miniaturized ion drives and electrospray thrusters are enabling deep-space CubeSat missions, solar system surveys, and swarm exploration concepts. These missions can ride-share on large launchers, separate en route, and then use their own EP systems to reach moons, asteroids, or even interplanetary orbits. Such flexibility would have been impossible just a decade ago.

Ultimately, as ion-drive power levels increase into the hundreds of kilowatts or megawatt class, electric propulsion could shorten travel times to outer planets, support long-range exploration of the asteroid belt, and form the backbone of a space-based transportation network. While high-thrust chemical engines will remain essential for landings and rapid burns, ion drives are rapidly assuming the role of the Solar System’s primary “cruise engines.”

Future Potential for Nuclear-Powered Ion-Drives

Nuclear electric propulsion (NEP) has long been recognized as the key to unlocking the full potential of ion drives, especially for missions beyond Mars where solar power becomes increasingly constrained. A space-based fission reactor can provide hundreds of kilowatts to megawatts of electrical power, enabling electric engines to operate at power levels far beyond what solar arrays can support. With continuous high-power thrust, NEP spacecraft could accumulate extraordinary Δv, enabling rapid transport of cargo to Mars, deep-space probes to the outer planets, and sustained exploration missions far from the Sun.

Current programs provide early glimpses into this future. NASA’s Kilopower project has demonstrated small reactor technology suitable for space applications, while the U.S., Russia, and China have all pursued conceptual megawatt-class NEP vehicles. These spacecraft envision clusters of Hall, ion, or advanced inductive thrusters operating in concert, each benefiting from the reactor’s steady, abundant power. Such systems could ferry large payloads, support multi-year missions, or operate high-power onboard scientific instruments for deep-space observation.

The advantages are transformative. NEP eliminates the dependence on sunlight, allowing electric propulsion to operate in regions where solar irradiance is too weak to sustain meaningful thrust. Missions to Jupiter, Saturn, Uranus, or Neptune—currently multi-decade endeavors—could be shortened significantly while carrying more payload. NEP platforms could also serve as orbital engines for crewed Mars missions, dramatically reducing the transit time and improving astronaut safety by minimizing exposure to cosmic radiation.

Challenges remain substantial. Space reactors must be designed to survive launch stresses, operate for years without maintenance, and dissipate enormous amounts of heat through radiators that add mass and complexity. High-power electric thrusters must also overcome erosion, plasma instabilities, and thermal loads. Yet, the convergence of reactor miniaturization and high-power EP development suggests that practical NEP spacecraft may emerge within the next two decades. Their impact on deep-space exploration could be as revolutionary as the ion drive itself.

Inherent Limitations of Ion-Drive Propulsion

Despite their extraordinary efficiency, ion drives face fundamental limitations rooted in the physics of electric propulsion. The most important is low thrust. Even high-power ion engines produce only fractions of a newton, meaning spacecraft must accelerate very slowly. While this is acceptable for planned, long-duration missions, it makes EP unsuitable for launch, landing, rendezvous under tight time constraints, or rapid evasive maneuvers. Chemical or nuclear thermal propulsion will always be needed in mission phases where instantaneous thrust is critical.

Electric propulsion is also heavily dependent on electrical power, which introduces mass and design constraints. Large solar arrays or nuclear reactors are required to feed multi-kilowatt or megawatt-class engines. These systems add complexity, require extensive thermal management, and can dominate spacecraft mass budgets. For some missions, the power system’s mass offsets the propellant savings provided by electric propulsion, complicating the trade-space for mission designers.

Another limitation involves lifetime and erosion. Gridded ion engines suffer from grid sputtering, while Hall thrusters gradually erode their discharge channels and cathodes. These wear processes can limit operational lifetimes and must be mitigated through materials engineering, magnetic shielding, or electrodeless designs. Although many current EP systems can operate for thousands of hours, future megawatt-class engines will require unprecedented durability. Electrodeless concepts like RMF-FRC thrusters aim to address this but are not yet operational.

Finally, propellant availability and handling create practical challenges. Xenon is expensive and globally limited, driving the industry toward krypton or iodine alternatives. Krypton reduces performance; iodine introduces materials and handling complexities. In addition, plasma plumes can cause contamination or erosion of nearby spacecraft structures if not carefully managed. These factors do not diminish the immense value of ion propulsion but remind us that it is not a universal solution. Instead, it is a powerful tool best applied where its strengths—efficiency, precision, and cumulative Δv—outweigh its inherent trade-offs.

Conclusion: The Quiet Workhorses of the Space Age

Ion drives don’t roar off the pad or leave towering plumes of fire in their wake. They whisper. Yet that whisper is reshaping the architecture of spaceflight. By trading brute-force thrust for extreme efficiency and long operating lifetimes, electric propulsion has turned station-keeping into an art form, enabled all-electric GEO platforms, and carried deep-space probes on intricate multi-target journeys that would be impractical with chemical rockets alone. What began as a niche technology for a few experimental missions is now woven into the fabric of commercial constellations, government satellites, and flagship planetary explorers.

Looking across the technology landscape—from gridded ion engines and Hall thrusters to electrosprays, RMF plasmoids, and ambitious nuclear-electric concepts—it’s clear that “ion drives” are not a single invention but an evolving ecosystem. Universities and national labs are pushing the physics and materials; companies are industrializing the hardware; and space agencies are designing missions that assume electric propulsion as a given, not a luxury. The trajectory points toward higher power, greater flexibility, and deeper integration into mission design, especially as solar arrays improve and space-qualified reactors move from study to flight hardware.

At the same time, the limitations of electric propulsion are not going away. Low thrust, heavy power systems, erosion, and propellant constraints ensure that ion drives will complement rather than replace high-thrust chemical and, potentially, nuclear-thermal rockets. But that division of labor is itself powerful: fast, impulsive systems to escape gravity wells and land on worlds; quiet, persistent ion engines to do the hard, slow work of moving mass around the Solar System. If we do build a true spacefaring civilization—with depots, tugs, stations, and robotic explorers crisscrossing interplanetary space—it is very likely that most of that invisible traffic will be driven not by explosions, but by the steady, ghostly glow of ion propulsion.

References

-

Ion Drive Propulsion: Types, Development, and Future Prospects (PDF)

-

NASA – Ion Propulsion: NASA’s Dawn and Deep Space 1 Missions

-

NASA Glenn – Solar Electric Propulsion (SEP) Project Overview

-

PEPL – Plasmadynamics & Electric Propulsion Laboratory, University of Michigan

-

Princeton EPPDyL – Electric Propulsion and Plasma Dynamics Lab

-

Georgia Tech HPEPL – High-Power Electric Propulsion Laboratory

-

MDPI Aerospace – “The Rotating Magnetic Field (RMF) Plasma Thruster”

-

Fortune Business Insights – Electric Propulsion Satellite Market 2025–2032

-

EU CORDIS – In-Space Electric Propulsion: Powering the Future EU Space Ecosystem

-

Emergen Research – Top Companies in the Satellite Electric Propulsion Market